Highly Integrated and Ultra Compact Power Modules for Embedded Drive Applications

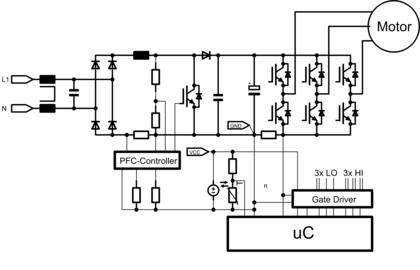

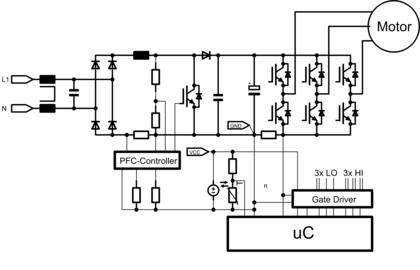

An embedded drive circuit consists of an input rectifier, PFC boost stage and a three-phase output inverter. Depending on the application, the best choice of module for this circuit is a highly integrated IPM (intelligent power module) or a very flexible PIM (power integrated module). The IPM also has the logic components and gate drives required for power switches. The PIM provides just the power components so the gate drive has to be mounted on the system's PCB.

Two key requirements for electronically controlled motors embedded in pumps, compressors, fans and other such applications are:

- Power factor correction (PFC): PFC is mandatory for drives connected to the public power grid.

- Hermetic motor integration: A hermetically sealed, integrated motor requires a compact design and thermal management. Interior space is limited and a hermetic seal prevents any airflow from reaching components on the system's PCB board. The heat generated by gate drives, shunt resistors and the like has to be dissipated by a connected heat sink.

IPM

Intelligent power modules (IPMs) are needed to achieve the functional integration and power density necessary for this type of design. The extent to which IPMs are integrated varies. At the minimum, a standard IPM features a simple three-phase inverter bridge with a compatible gate driver. With more extensive integrated modules, engineers can create more compact designs and take advantage of a proven combination of power components and gate driver circuit, the most critical elements in the inverter's design. This mitigates the risk associated with circuit design, speeds up development and slashes time to market.

Power semiconductors, integrated circuits, SMDs and resistors integrated into the substrate can all be combined with the benefit of thick-film technology, thereby maximizing the new flowIPM 1B power modules' functional integration. This design incorporates all active power components for a three-phase inverter with active power factor correction (APFC), including capacitors to compensate for inductive loops, shunts for sensing current, a PFC controller with its surrounding circuit to serve as a voltage divider, and DC capacitors.

The PFC frequency and output voltage are programmed using two external resistors. A version equipped with just the PFC switch gate driver is available if the external microcontroller used for the inverter is to also control PFC. This may require a negative supply and an amplifier for the PFC current signal. The microcontroller's ground connection is on the positive side of the PFC shunt resistor. A direct connection to the microcontroller is not possible. The optional Press-fit interconnection affords engineers greater leeway in designing the target application. What is more, the power module's more extensive functional integration shifts the R&D effort from the drive's developer to the module manufacturer. The drive's manufacturer has to invest far less effort in development, yet enjoys far greater flexibility in defining functions and calibrating switching behavior

PIM (CIP)

An application designed for a 4-kHz PWM frequency and for a 16-kHz application are not created equal, and their filter effort and switching loss have to be optimized in different ways. A vector control-based inverter requires more effort to measure current signals. Only the power components – the input rectifier, PFC boost stage and three-phase output inverter – are integrated in PIM modules. The gate drive circuit and other logic circuits have to be mounted on the external PCB. An integrated DC capacitor is provided to reduce inductance and enable ultra fast turn-off for the PFC switch.

Some versions of these modules provide a shunt resistor to sense current for PFC or inverter control. The emitter structure in the low-side switches is open so three external shunt resistors may be connected for vector control-based inverter designs. A temperature sensor provides the heat sink temperature at the module's position.

Vincotech’s product portfolio for embedded drives

Space is tight in embedded drive systems, and their compact, hermetical design makes it difficult to dissipate the heat generated by so many electronic components.

Vincotech’s power module portfolio for embedded drives features 600V and 1200V intelligent power modules (IPMs) as well as power integrated modules with PFC circuits (PIM+PFC) that achieve the highest level of integration of any power module available on the market today. And that makes these modules the best solution for space-constrained mechanical environments.

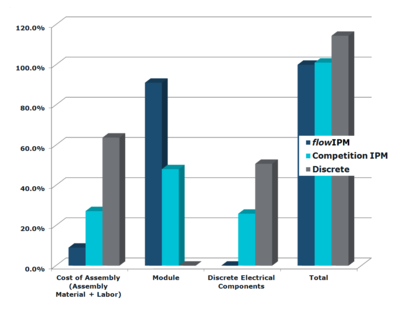

The overall system's size, cost, and time to market can be reduced by integrating all of a motor drive's functional blocks, apart from the input filter, DC capacitor and microcontroller.

Protection circuitry is tuned to match the power device's capability and factory-tested to improve the system's reliability. A great deal of space is saved with highly integrated components and bare power chips to achieve a much smaller footprint than that of discrete designs.

Motor drive assembly is streamlined and simplified with fewer external components and smart isolation techniques. The ceramic sheet used in thick-film technology improves the module's thermal performance by providing the best possible direct cooling for power components.

Vincotech’s power modules for embedded drives come in very compact housings that can be equipped with Press-fit pins. Press-fit technology reduces PCB assembly time and effort considerably by eliminating the need for soldering. This cuts process time and costs, and boosts production output.

The module's creepage and clearance distances fulfill the applicable industrial standards. There are no special requirements regarding the shape of the heat sink.

The thermal interconnection between the power module and the heat sink is vastly improved by pre-applying phase-change material. Vincotech’s in-house screen-printing process deposits the material with great precision to achieve the proper thickness. The material can be optimized for maximum heat transfer capability.

Conclusion

Vincotech’s product portfolio provides the functional integration and power density that engineers need to design embedded drive systems. The outstanding level of integration achieved by Vincotech’s intelligent power modules enables system engineers to come up with more compact designs and to take advantage of a proven combination of power components and gate drive circuits, which happen to be the most critical elements in the inverter’s design. This mitigates the risk associated with circuit design, speeds up development, and dramatically reduces time to market.