IPM (CIP/PIM+PFC)

Structure

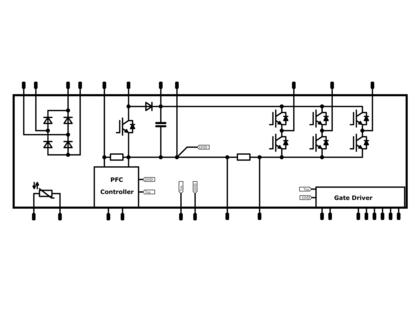

The most important feature of an Intelligent Power Module (IPM) device alongside the PIM, sixpack or PFC topology is its integrated driver circuit.

Vincotech 600 V IPMs combine single phase input rectifier, PFC circuit and three phase motor inverter (CIP – Converter, Inverter, PFC). They also integrate current sensing feature and gate drives including the entire bootstrap power supply circuits, under-voltage lockout, and over-current protection. All of them are also equipped with a thermal sensor to support the thermal design by the drive’s manufacturer.

Application

Embedded drive systems integrate drives and electric motor to reduce the space occupancy thanks to their compact and hermetical design. Since they are dedicated to specific applications, design engineers can optimize them to reduce the size and cost of the final product and increase the reliability and performance. The overall system’s size, cost, and time to market can be slashed by considerably increasing the level of integration.

Vincotech IPMs achieve the highest level of integration of any power module available on the market today, representing the best solution for such space-constrained mechanical environments.

IPMs are widely used in major appliances – otherwise known as white goods – because they are very functional and easy to use. Vincotech IPMs are most often used in fan and pump applications as they allow for more compact designs than the usual power module.

How it works

An IPM is a full comprehensive power module encompassing all the standard stages of a power conversion process with the additional benefit of the integrated driver circuit. In many cases, the module can be driven by nothing more than PWM signals sent directly from the microcontroller. Other passive components are built into Vincotech IPMs alongside the integrated driver. These are the complete bootstrap circuit, a small DC capacitor to close the high frequency loop inside the power module, and shunt resistors to measure the current.

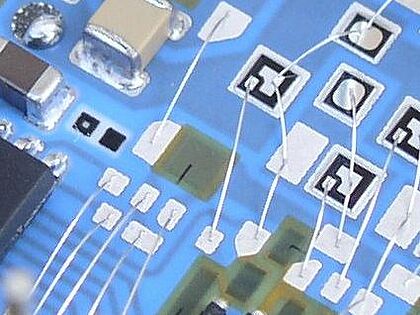

Thick-film Technology

An outstanding level of integration is achieved by the use of thick-film technology in Vincotech IPMs. Different layers of conduction and isolating materials are printed on a ceramic sheet. The layers can build tracks, pads, and resistors that can be laser-trimmed in such a way to achieve high levels of accuracy. This technology enables high thermal conductivity and the possibility to create PCB-like layouts.

Thick-film is a very mature technology. It has already been used for several years, especially in critical applications, e.g. the automotive industry.

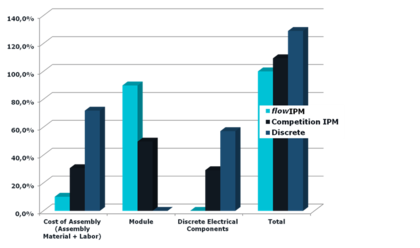

Cost Benchmarks

The high level of integration of Vincotech’s intelligent power module results in a significant system level cost saving and represents the best solution for space-constrained and cost-driven mechanical environments.

To learn more and see the full range of products, follow this link: IPM (CIP/PIM+PFC).