Drives for HVAC are addressed by a wide variety of power modules. Nowadays, highly integrated power modules are the solution of choice in such applications as higher integration and more complex subsystems are some of the current trends in the Industrial market.

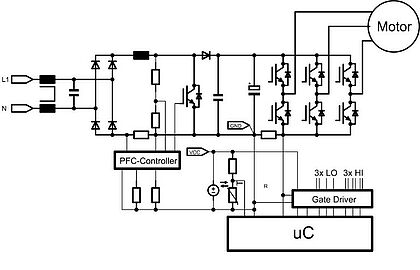

Intelligent power modules (IPMs) are needed to achieve the functional integration and power density necessary for this type of design. The extent to which IPMs are integrated varies. At the minimum, a standard IPM features a simple three-phase inverter bridge with a compatible gate driver. With more extensive integrated modules, engineers can create more compact designs and take advantage of a proven combination of power components and gate driver circuit, the most critical elements in the inverter's design. This mitigates the risk associated with circuit design, speeds up development and slashes time to market.

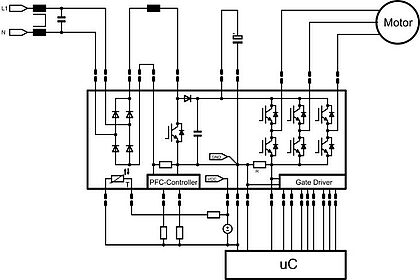

PIM with integrated PFC are also used in such applications as they offer the necessary level of integration while keeping flexibility in the design of the PCB. Only the power components – the input rectifier, PFC boost stage and three-phase output inverter – are integrated in such modules. The gate drive circuit and other logic circuits have to be mounted on the external PCB. An integrated DC capacitor is provided to reduce inductance and enable ultra-fast turn-off for the PFC switch. More recently, the interleaved PFC configuration embedded in PIMs provides high level of integration while enhancing the power conversion efficiency.